Netstal

NETSTAL PET 2000-3700 R PREFORM SYSTEMS (YR 2012) Used Injection Moulding Machine

NETSTAL PET 2000-3700 R PREFORM SYSTEMS (YR 2012) Used Injection Moulding Machine

Couldn't load pickup availability

NETSTAL PET 2000-3700 R PREFORM SYSTEMS (YR 2012) Used Injection Moulding Machine for sale

- NETSTAL PET 2000-3700 R

Netstal PET 2000-3700 R with clamping force of 2000 kN. Power consumption of a single machine for processing 1 kg raw PET does not exceed 0.215 kWh. Extrusion efficiency is at least 550 kg/h.

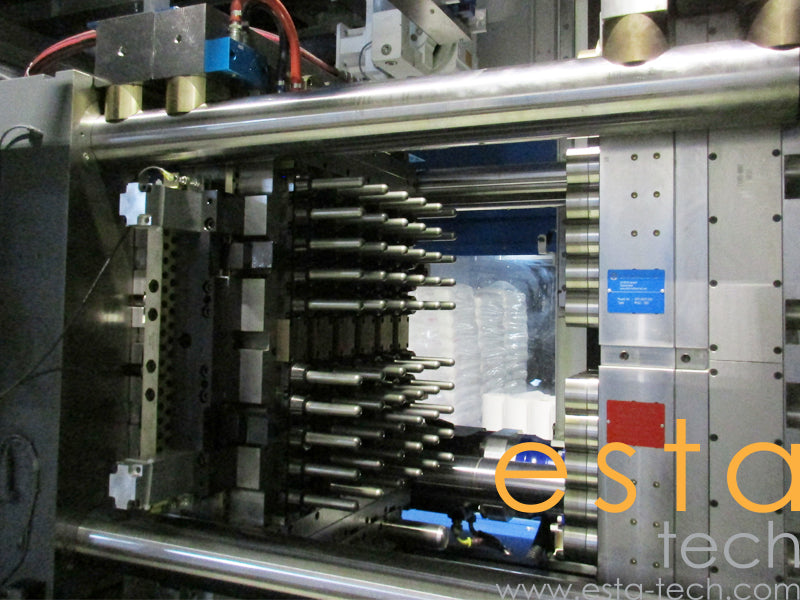

- 60 cav. Preform Injection Mould - OTTO HOFSTETTER AG

Number of cavities: 60

Hotrunner system with individually heated nozzles and pneumatic needle shut-off. The efficiency of press-form is at least 20 000 units/h

(calculated for 28 g product weight/product wall thickness 2.6 mm)

(Molds 26.5+28 gr and 30+34.5+39 gr PET preforms of PCO1881)

- PET drying system PIOVAN

PET drying system model DP644 for max throughput of 560 kg/h

Drying hopper model TN4000

Hopper capacity 4000 litres.

- MOULD CONDITIONING

Mould Conditioning Unit model RPA1200

it prevents the condensation of ambient air on the surface of the Mould

1200 m3/h process airflow

Max 35°C and max 90% R.H. environmental limit conditions to maintain a good working efficiency of the unit.

- WATER CHILLING

Air-cooled water chiller mod. CA4222

Main technical characteristics:

For indoor & outdoor applications

Nominal cooling capacity (ambient temp. 25°C - set point 15°C): 487 kW

Actual cooling capacity at the following conditions: 310 kW

Design ambient temp.: max 37°C

Design set point: 7°C

Min Max Ambient temp: -20°C / +49°C

Flow rate (m3/h): 18/42

Galvanised steel vertical water tank -Capacity: 3000 lt

Please contact us for more details and price.

Share