Arburg

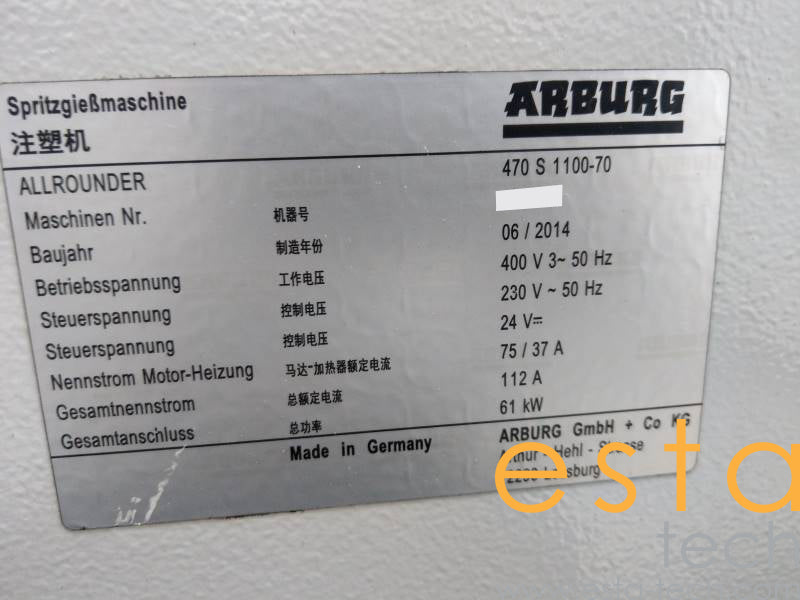

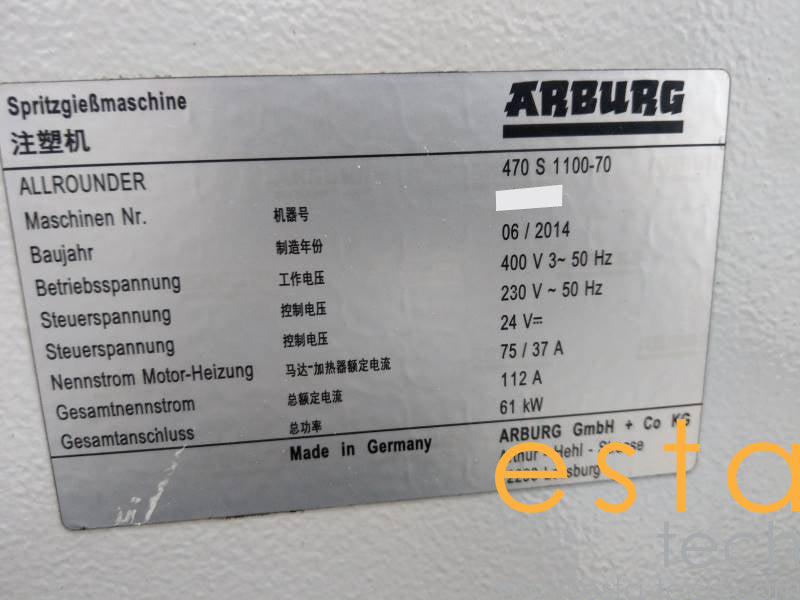

ARBURG ALLROUNDER 470S 1100-70 (YR 2014) Used Plastic Injection Moulding Machine

ARBURG ALLROUNDER 470S 1100-70 (YR 2014) Used Plastic Injection Moulding Machine

Couldn't load pickup availability

ARBURG ALLROUNDER 470S 1100-70 (YR 2014) Used Plastic Injection Moulding Machine for sale

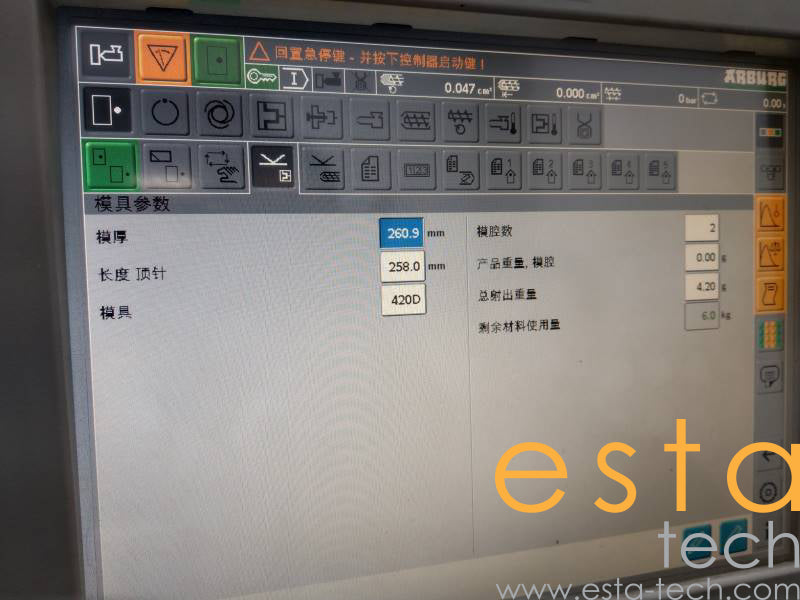

USED FOR LOUD SPEAKER PART PRODUCTION

Package Include:

- ALLROUNDER 470S 1100-70 PLASTIC INJECTION MOULDING MACHINE

- Robot system: MULTILIFT V cantilever

- Electric conveyor belt, programmable

- HB-Therm Temperature control unit

- MOTAN Luxor CA15 Compressed air dryer

MACHINE WORKING HRS (APPROX.): 951

Year: 2014

Model : ALLROUNDER 470S 1100-70

Opening stroke: 500 mm

Screw Size: 18mm

Injection volume: 22 cm3

Injection Speed: 500mm/s

Ejector stroke: 175 mm

- Highly wear resistant plasticising cylinder assy 18 mm (without nozzle)

- 1st core pull control for simultaneous

- Air blow unit 1 with pressure reduction valve

- Electric conveyor belt, programmable

- SELOGICA control system

- 4 freely programmable inputs/outputs on terminal strips on printed circuit board

- Controller extension for additional signals

- EUROMAP 65 chip card

- Mobile SELOGICA AMS

- Connection for mobile SELOGICA AMS

- 9 electrical heating control circuits for mould heating, each with max. 2 kW / 230 V, (HAN 24 E, assignment according to HASCO, without connection cable from machine to mould) suitable for control circuits with a max. temperature increase of 20 deg./s

- Interface for temperature control units for mould, 20 mA (max. 6 units can be connected)

ROBOT SYSTEM: MULTILIFT V CANTILEVER

ROBOT WORKING HRS (APPROX.): 14

Handling weight: max. 15 kg

Z - axis (transversal to machine's longitudinal axis)

stroke: 1,800 mm

max. speed: 3.0 m/s

X - axis (parallel to machine's longitudinal axis)

stroke: 500 mm

max. speed: 2.0 m/s

Y - axis (vertical axis)

stroke: 600 mm

max. speed: 2.7 m/s

max. handling weight: 15 kg (total of gripper, parts and additional axes)

Repetitive accuracy: +/- 0.1 mm

- X-axis stroke extended to 600 mm

- 4 vacuum system (suction capacity 23 l/min, incl. air-blow function, incl. vacuum switch for monitoring of parts, mounted near gripper, pneumatic hose connections by customer: plug-in and twist connectors for hose sizes DA 6 / DI 4, incl. valve control)

Please contact us for more details and price: info@esta-tech.com

MACHINE IS SOLD "AS IS, WHERE IS" SPECIFICATIONS ARE QUOTED TO THE BEST OF OUR KNOWLEDGE AND ARE SUBJECT TO YOUR VERIFICATION AND CORRECTION. SPECIFICATIONS, OPTIONS, ADDITIONAL EQUIPMENT ARE SUBJECT TO BUYER VERIFICATION & CORRECTION.

Share